Our Feature

Our Feature

Nationwide

Network

We are equipped with cutting-edge presses and fabrication machines and use advanced technology to deliver multiple articles with short turnaround.

Our Main Plant and No. 2 Plant are fully stocked with the latest servo presses, fiber lasers, and turret punch presses with auto tool changers. These and other cutting-edge machines are operated by engineers and factory workers with advanced skills and knowledge. This underpins our ability to handle small lots featuring multiple articles with short turnaround in addition to satisfying needs for a wide range of complex shapes and sizes, which creates customer satisfaction.

Strong

Foundation

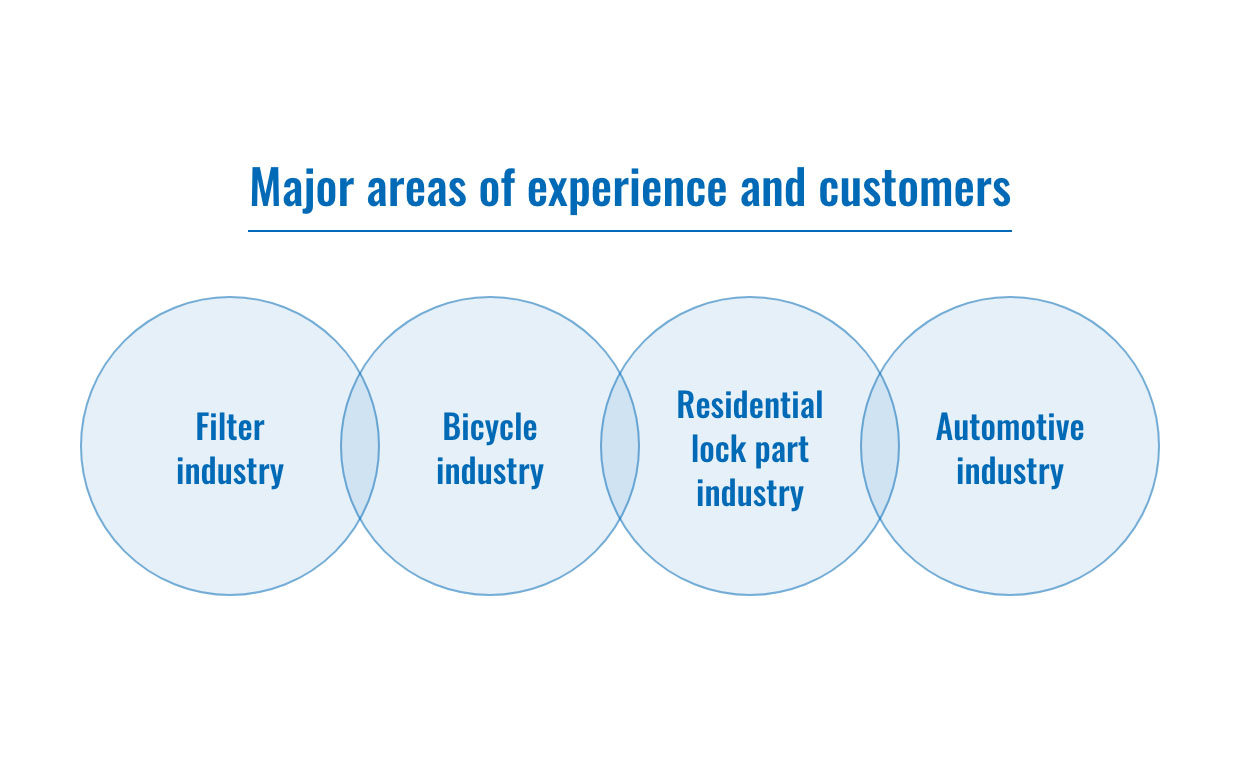

We deal directly with major manufacturers in many industries.

We have established longstanding relationships based on firmly rooted trust.

We deal directly with Japan’s top manufacturers in many industries, including makers of bicycle parts, filters for semiconductor manufacturing, and locks. We can confidently say that this is thanks to the strong trust-based relationships we have established and our reputation as a supplier with the desired techniques, quality control system, and scheduling flexibility.

Factory

Equipment

Through cooperation with partner companies,We provide one-stop service to surface finishing.

Metalworking sometimes involves plating, coating, electropolishing, and other forms of surface treatment in the final stage. We partner with other companies that perform these operations, and are thus positioned to include finishing work in our total package. Centrally managing multiple processes ensures high quality and helps reduce customers’ administrative man-hours.

We work with trusted partners to extend our menu of services to surface finishing.

■ Alumite treatment

The process of creating an anodic oxide coating on the surface of aluminium, which is soft and susceptible to scratches. A thick aluminium oxide film is artificially created to improve the abrasion and corrosion resistance of the base aluminium while doubling as a decorative finish among other functions.

■ Electropolishing

The process of melting metal surfaces by leveraging the principles of electrolysis to achieve a grinding effect. Electrochemically melting a metal removes imperceptible irregularities on its surface. Electropolishing achieves a uniformly smooth, mirrored finish while forming a robust oxide film that improves the corrosion resistance of the base metal.

■ Powder coating

The process of directly applying a powder coating to a metal and then heating and drying it to create a hard coating. This method is gaining popularity over ordinary solvent coating because it does not involve any organic solvent, reducing the impact on the environment and the human body.

■ Melamine coating

A type of baking coating in which two resins are combined, explaining why it is also referred to as synthetic resin baking coating. The coating is a combination of heat-hardened amino melamine resin and polyester alkyd resin.

■ Plating

Unichrome plating is the process of chromate-treating an electrogalvanized material with a solvent that includes fluorides. It is commonly referred to as bright chromate. It is a somewhat pale silver in color, and is used in most water faucets.